Spectacular Info About How To Build A Dynamometer

You can clamp one on to a spark plug lead.

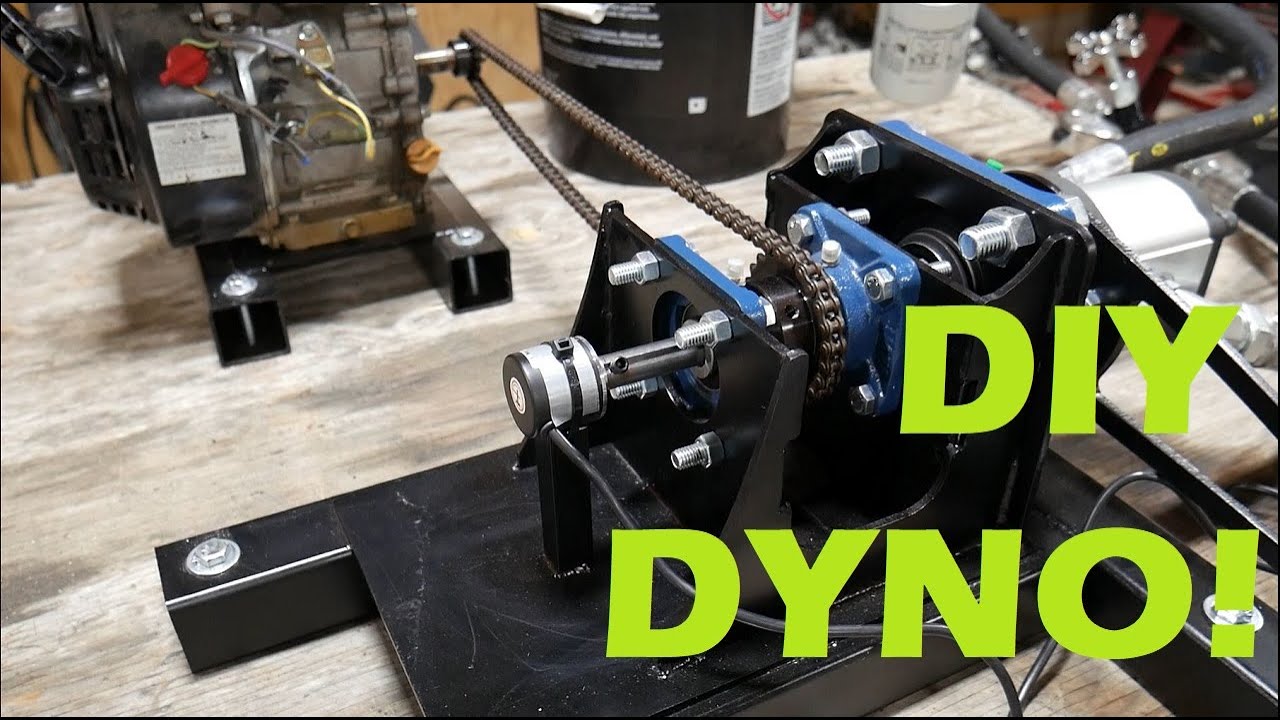

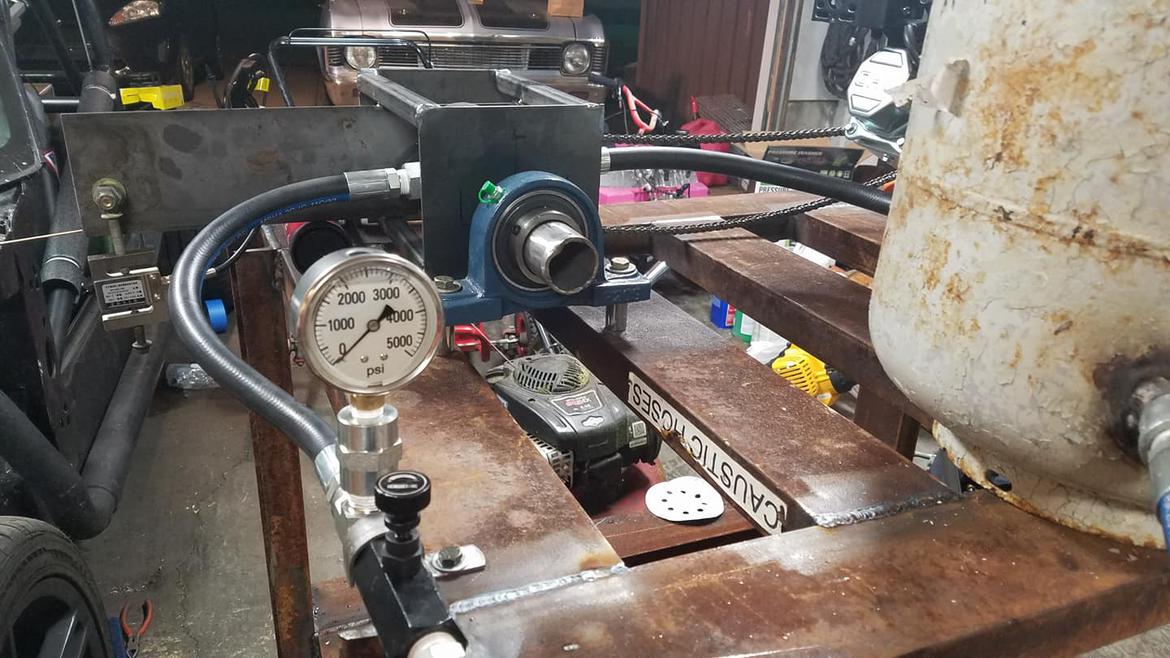

How to build a dynamometer. The idea is that you hook the two shafts together and apply a certain load (torque) to the test motor. Subscribe to see how i'm breaking it in with futures vi. How to build a homemade mechanical dynamometer.

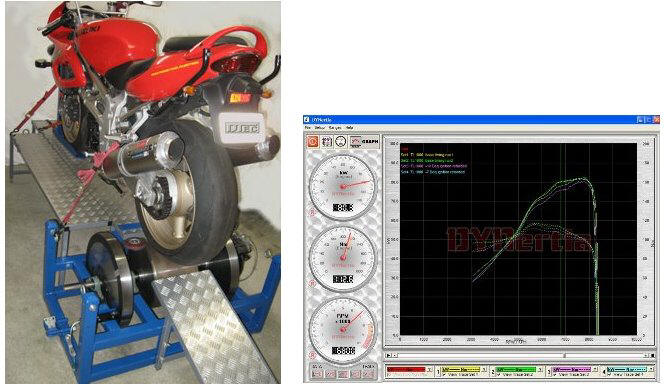

Gentlemen, when one uses a dynamometer, the braking device usually has a trunion support and at a specific radius from the center of the trunion it has a load cell that is. Use it as weighing machine easy to transport. Make sure power is not plugged in to the dyno.

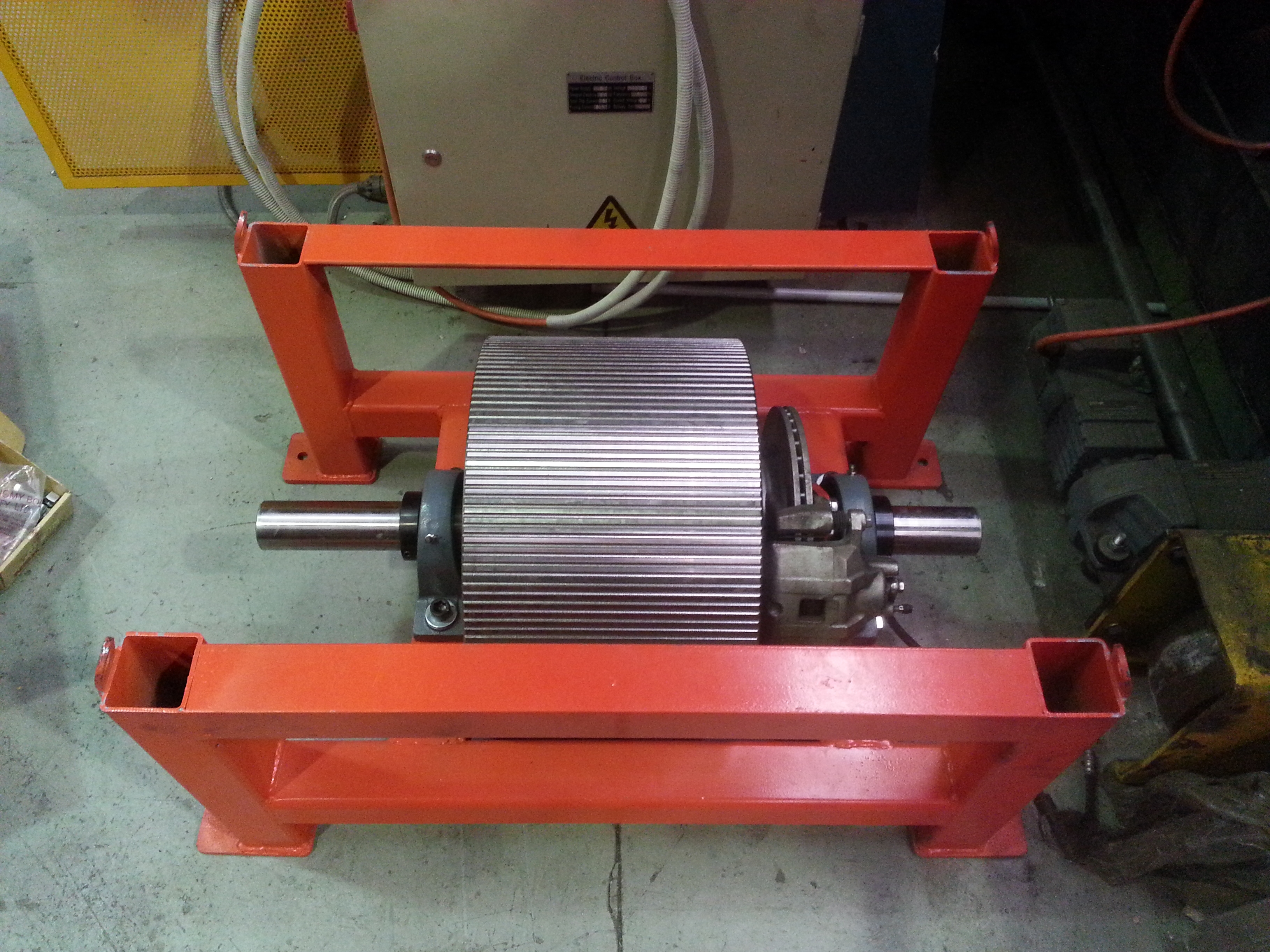

At the very least, you need to ensure that these are consistent: You know the torque applied if you know the input current (a) because you. This dyno is going to be used to measure the hp and characteristics of an electric motor.

Then, we place another nail in the upper part of the long wooden strip and. A dynamometer is usually defined as a device for measuring mechanical power, but in a broader sense can include measurement of force and torque also. This is part 1 of a do it yourself (diy) inertia dynamometer build.

I may have made a mistake using a window motor for the. Next, hook up a pickup coil to your ignition system. The first key is to ensure your setup is as consistent as possible.

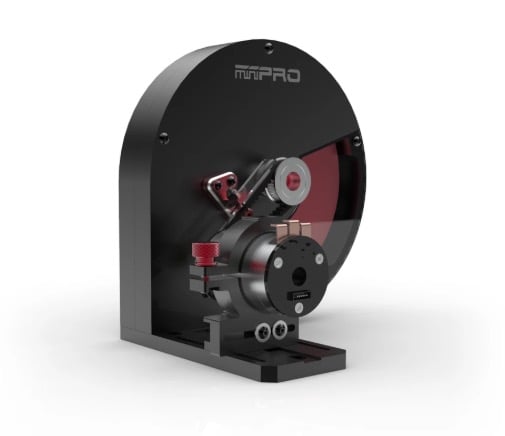

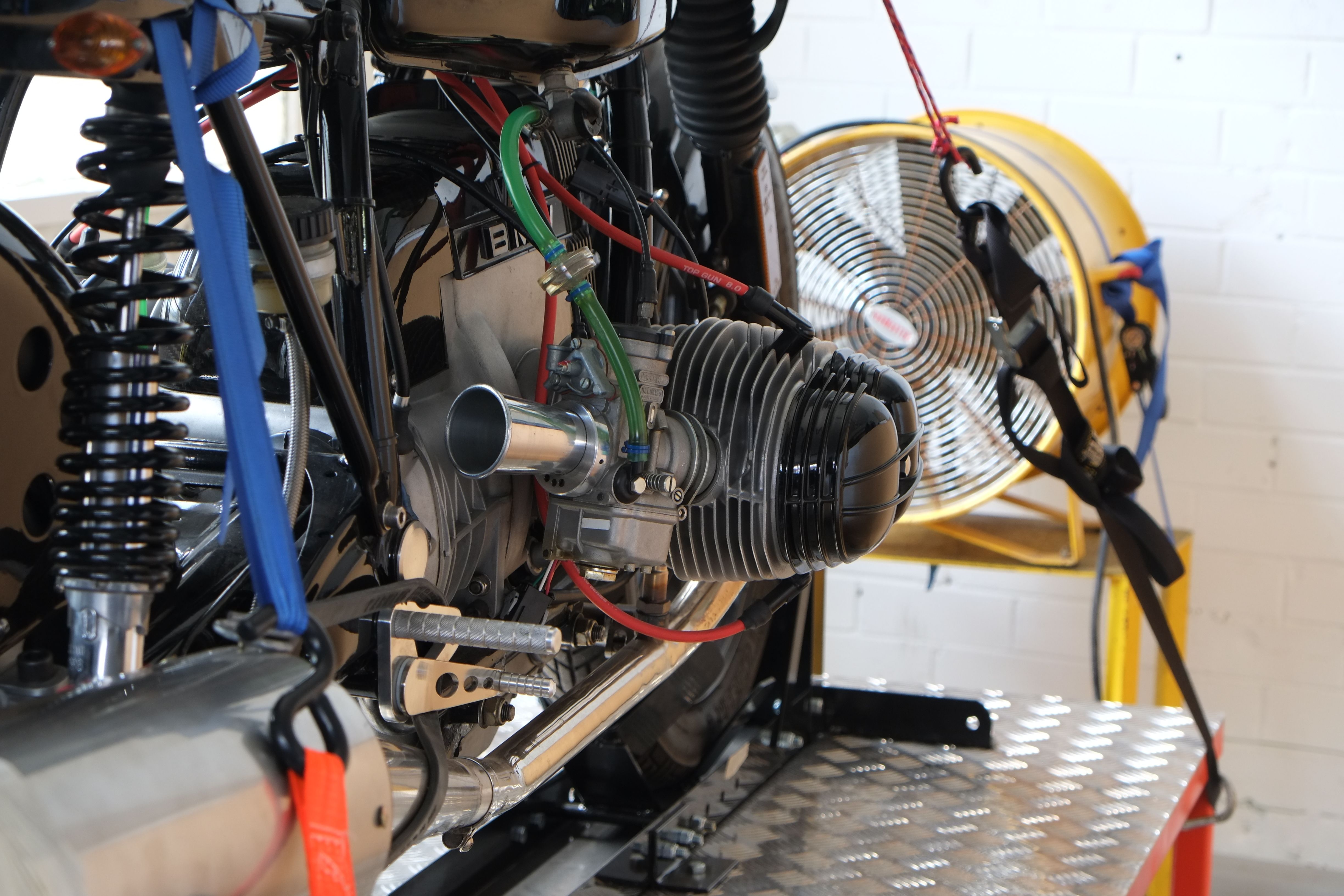

This is a version of the pony brake dynamometer used to check horse power and efficiency of a motor. Be able to measure the force to obtain the power of some engines. I design this friction torque meter to study the performance of the motor, gearbox, and other stuff.